I have purchased a small selection of bulkhead fittings from US Plastics, an online supplier of those and evidently a large variety of other plastic-related items. I am currently gearing up to procure another round of supplies, at which point I will be very close to the point of being able to fill the system with water.

Since I had to purchase fittings, it seemed like a good time to do some calculations and make sure I was sizing the plumbing appropriately. I assume a pump rate of 800 gph (it's a 1000 gph pump, but I am attempting to account for head loss). I can't seem to find the calculations (they must be in another spreadsheet), but for the moment I am assuming that the media will occupy about 30% of the GB space. The GB's max operational capacity is approximately 100 gallons. Thus, we will suppose 70 gallons will filter into the GB before the siphons start.

Given the above, the anticipated static fill time (the time it takes to fill completely before draining starts) should be about 315 seconds. A 1 inch diameter drain pipe should pull the water out of the GB in about 200 seconds. Figure in the constant fill rate, and the drain time jumps to 547 seconds (we'll call this the dynamic drain time), meaning it would take far longer to drain than to fill. At 1.5 inches of drain diameter, we should expect 124 seconds of dynamic drain time. That's better. At 2 inches, it should drain all 70 gallons in about 59 seconds.

Now, I can only cut these holes once, and I am slightly concerned that the length of the bed will cause one side to become more stagnant than the other, should I place the drain in one corner. The alternative is therefore to add a second drain. Two 1.5" diameter drains equals one 2.12" diameter drain in drain area, so the dynamic drain time would be around 52 seconds. Two 2" drains (equivalent to one 2.83" diameter drain) will reduce the drain time to 27 seconds. These times do assume sufficient out-piping, which means I would probably need to enlarge at least a portion of the pipe running down to the DWC.

Whether or not I really need the second drain is up for debate, but by at least installing the bulkhead fitting now, I can always add the actual drain later (and otherwise just plug the hole if it need not be used. If I do go with the larger size pipe, or two of them for that matter, I will very likely need to contend with a siphon start issue. Thinking back to the pull-start siphon I experimented with several months ago, I decided it might be good to find a way to build that in. Putting two bulkheads next to each other, however, did not seem like a good idea, and the loss of GB real-estate was becoming bothersome.

One potential solution, which I will be experimenting with as soon as the fittings arrive, is to put the start-pipe assembly above the bulkhead, rather than below it. In concept, there would be only a single pipe and single bulkhead fitting. The pipe would tee immediately above the fitting, and proceed up at full diameter and out at the start-pipe diameter (1/2" most likely). The start pipe connection would do a bend and then run parallel to the main drain, terminating just below the top of the main. The start pipe would therefore set the max water height in the GB.

Two siphons should not pose any special difficulty, as long as they are drained together. If the main (pull-started) siphon is closest to the out-pipe, and the secondary siphon connects into it just before the out-pipe, the secondary siphon should get pull-started by the main siphon. That is, once the main siphon trips, it should pull sufficient vacuum on the drain plumbing to forced the second siphon to start. The effect will be a three-stage drain: start, primary, secondary.

It may be better to put the primary siphon upstream of the secondary, but my only concern is that the long horizontal run will cause problems for primary siphon start.

Regardless of how the siphons are started or how fast they flow, this action has an effect on the DWC tank: given the dimensions of the DWC, a 70 gallon ebb-and-flow will equate to approximately 5.6" of rise and fall. Consequently, the pump will need to gather water from as close to bottom as possible. It should be noted that this height changes is slightly more than 50% of the maximum water height for the DWC. Should it be determined that less water is required in the GB to trip the siphon, then this percentage will be reduced accordingly. (For instance, a 50 gallon ebb-and-flow will equate to a 4" rise and fall.)

I plan to position the water pump outside the DWC, piped so that its inlet it always submerged. I may need to find a decent filter material to keep debris from entering the pump. One of the bulkhead fittings I acquired is intended to go through the wall of the DWC. This is mainly to ensure that the pump can be properly primed before starting, as it is not self-priming.

Testing will hopefully commence soon!

Showing posts with label plumbing. Show all posts

Showing posts with label plumbing. Show all posts

2016-05-11

2016-01-18

Siphon Testing - Round 2, Brief Findings

|

| The standpipe and funnel assembly |

Effects Drain Pipe Diameter and Length on Drain Times

As you can see on the chart above, the 3/4" drain pipe length appears to affect drain times fairly predictably. Unfortunately the drain rate increases were not as high as I was hoping them to be. The first test (left-most dot) is without any additional drain pipe. The X axis is pipe length, the Y axis is the seconds to drain - that is, the time from siphon-start to the siphon-end burp.

The fastest drain time was recorded while testing without the funnel in place. I only ran one test of that sort, however, so that result might be an outlier. I noticed that in only one or two tests the drain rate would be extremely fast, but in the remainder of tests it seemed to hold fairly constant.

For the next series of tests, I used a bushing to convert to 1" after the bulkhead fitting. The idea for this was to reduce static pressure and allow the water to flow faster. Thus, 1" drain pipe would be used. As this was larger than 3/4", technically it would have operated at slightly higher pressure.

The majority of the 30" tests were done with a snorkel bell. The snorkel was used primarily to watch the pressure inside the bell. The most important things to note here are that the drain rate remained constant for most of the tests, between 35 and 40 seconds for nearly every test, and seemingly regardless of drain length. Again, in the chart above, the X axis is for length, the Y axis for drain time (in seconds).

For the next series of tests, I used a bushing to convert to 1" after the bulkhead fitting. The idea for this was to reduce static pressure and allow the water to flow faster. Thus, 1" drain pipe would be used. As this was larger than 3/4", technically it would have operated at slightly higher pressure.

The majority of the 30" tests were done with a snorkel bell. The snorkel was used primarily to watch the pressure inside the bell. The most important things to note here are that the drain rate remained constant for most of the tests, between 35 and 40 seconds for nearly every test, and seemingly regardless of drain length. Again, in the chart above, the X axis is for length, the Y axis for drain time (in seconds).

I would hypothesize, based on these data, that the ideal solution is to maintain a constant pipe diameter throughout the bell siphon.

|

| The snorkel test bell assembly. |

Bell Water Level Observations

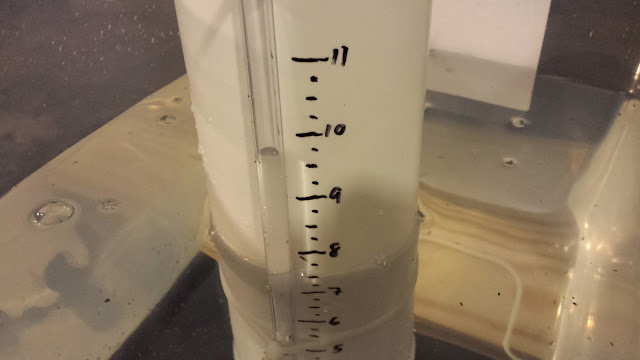

My snorkel bell rises quite high above the top of the standpipe. The siphon had no problem starting, given sufficient flow - more on that later. The interesting thing I noticed was that after the siphon started, the water level in the snorkel rose by at least 1", usually 2", and in the case of using 3/4" drain pipe it rose by over 4"! This level would usually slowly drop as the water level in the source reservoir was depleted. The informal relation seemed to be: the faster the siphon, the higher the level reading on the snorkel.

Compared to the 1" drain pipe, the 3/4" drain pipe appeared to deliver significantly more suction once siphoning began. I had marked my bell with inch indicators up to 11", but the water level in the snorkel tube quickly shot above where the 12" would have been. All 1" pipe tests delivered consistent results: snorkel level rose by about 1.5" from the top of the standpipe, and drain times were consistent.

It was also interesting to watch the water level shoot up once the siphon started in earnest, and to drop as it was breaking. I was able to observe the transition from spillover to drain with ease. Another interesting test would be to verify if the water level in the snorkel matches that inside the bell.

|

| Siphon in action: Note that the level of the tank is around 7.5", whereas the water level in the siphon appears to be nearly 10" |

Slow Fill Observations

For the slow-fill tests, I rigged the supply to provide approximately 0.0358 cubic centimeters per second of water. This figure was calculated based on observing the rise of the water in the tank and calculating it against the estimated tank geometry. The drain was left at 30" of 3/4" pipe for all the tests. I used the standard bell for all but the final test.

I first observed the standpipe without the bell, to ensure that the rate would not quickly flood the standpipe. Having observed this, I replaced the bell and waited to see if the siphon would start. It did not. I then added the funnel back onto the standpipe. The water seemed to flood into the standpipe a little bit better, but the rate was still much too slow to trigger a full siphon.

I added one 90-degree bend to the bottom of the standpipe, but it had no effect. I added a second 90-degree, and finally it achieved siphon. I repeated this test without the funnel, and came up with generally the same results.

Slow Fill Conclusions

Fill rate is key for siphon start. I hypothesize that the fill rate must overcome the non-siphon drain rate in order to build a solid column of water in the pipe. One the water column has been established, the siphon will start.

If the fill rate cannot be altered, then adding fittings to create back-pressure also works. I did not use a trap-style drain configuration, as I prefer to let the bell breathe while the tank fills. I am also not yet convinced that the trap is superior to simply two downward-trending bends. The two 90-degree bends - added back-to-back to the very end of the drain - added sufficient back-pressure in my experiments. They also did not immediately appear to harm siphon drain rates.

We must realize that the siphon is a dynamic system and governed by flow rates. As such, the addition of snorkels, bends, reducers, etc, to "fine tune" the siphon will work only so long as the flow rates are appropriate. In other words, these things do not guarantee a better (or even a functional) siphon. You are, in effect, simply moving numbers around.

The standpipe funnel also does not necessarily yield a better siphon, though I suspect it did allow the siphon to trip faster, moving from spillover to drain much quicker than with the straight, unadorned standpipe. This is, after all, the reason people claim to employ a funnel on their standpipes.

In future experiments, I would like to examine the rates of inflow and outflow, to understand better how the addition of back-pressure solves siphon-start problems. I would also be curious to see if the drain pipe length has an effect on siphon-start; in all my slow-start tests, I kept the drain pipe length constant. Finally, it would be interesting to see if the water level inside the bell is an indicator of the rate of drain.

In future experiments, I would like to examine the rates of inflow and outflow, to understand better how the addition of back-pressure solves siphon-start problems. I would also be curious to see if the drain pipe length has an effect on siphon-start; in all my slow-start tests, I kept the drain pipe length constant. Finally, it would be interesting to see if the water level inside the bell is an indicator of the rate of drain.

In no cases did the 1/8" emergency drain hole in the standpipe inhibit siphon operation or tank fill.

All Drain Test Results

Below are the results from all the tests. The last two columns are the calculated cubic centimeters per second of drain rate, and the calculated time it should have taken for draining to complete. As can be seen, the wide variability in the results suggest further testing. The 1" tests are also curious, in that they were extremely consistent and always significantly longer than the calculated times. I suspect the reason for this is the 3/4" standpipe, and/or the bushing to go from 3/4" to 1" pipe. I plan on performing additional tests using 1" standpipe, once I have a 1" bulkhead fitting.

| 3/4" Diameter Drain Pipe Tests | ||||

| Test # | length | drain time (seconds) | calc cm3/s | calc t |

| 1 | 0 | 44 | n/a | n/a |

| 2 | 11 | 26 | 665.93 | 29.90401379 |

| 3 | 28 | 21 | 1,062.46 | 18.74333258 |

| 9 | 13 | 21 | 723.94 | 27.50769186 |

| 10 | 7.5 | 26 | 531.23 | 37.48666515 |

| 11 | 30 | 19 | 1,099.75 | 18.10777959 |

| 16 | 30 | 22 | 1,099.75 | 18.10777959 |

| 17 - no funnel | 30 | 15 | 1,099.75 | 18.10777959 |

| 1" Diameter Drain Pipe Tests | ||||

| Test # | length | drain time (seconds) | calc cm3/s | calc t |

| 4 | 6 | 44 | 874.35 | 22.77575217 |

| 5 | 12 | 40 | 1,236.52 | 16.10488881 |

| 6a | 30 | 20 | 1,955.11 | 10.18562602 |

| 6b | 30 | 41 | 1,955.11 | 10.18562602 |

| 7a - snorkel | 12 | 36 | 1,236.52 | 16.10488881 |

| 7b - snorkel | 12 | 36 | 1,236.52 | 16.10488881 |

| 7c - snorkel | 12 | 36 | 1,236.52 | 16.10488881 |

| 7d - snorkel | 12 | 35 | 1,236.52 | 16.10488881 |

| 8 | 6 | 35 | 874.35 | 22.77575217 |

2016-01-15

My Trial System Design and Project Plan

Very soon after I had devoured the book Aquaponic Gardening: A Step-By-Step Guide to Raising Vegetables and Fish Together, by Sylvia Bernstein (ISBN # 978-0865717015), I set out to draft my first system. Here's a peek:

|

| The trial system configuration |

Goals

My goals for this system:- Keep it small, but large enough so that we can stabilize the system and keep it running for at least one whole season.

- Minimal investment in structure - let's not build a huge greenhouse before we know we can actually make this work.

- Use a nutrient solution transport scheme that has had high reported success and minimal impact on the fish.

- Make the framing components extremely easy and cheap to build (the picture above is not accurate to the final specs)

- Large plumbing for minimal cleaning.

- Keep the pump accessible.

- Design for maintenance.

- Design to mitigate failures and fish-death.

- Design for future expansion.

System Design - Overview

To achieve these goals, I have set out to do the following:

|

| Plumbing View - Grow bed assembly removed for clarity |

- The system is a 200 gallon cone-bottom fish tank, a 100 gallon sump, and two 50 gallon grow-beds. This technically gives me a 1:2 ratio of fish tank to grow-bed space, where the preferred ratio is 1:1 or 2:1. I can compensate by simply not adding as many fish.

- By putting this on my back porch, I have an enclosed space that I can manage and is convenient for monitoring and upkeep. No structure builds required. The downside is that I need to supply auxiliary lighting, which means either buying or building lights.

- I toyed around with CHOP-1 and CHOP-2, and finally settled on CHOP-1. While I'm not convinced of the problems that detractors of CHOP-2 go on about, CHOP-1 plumbing is easier by far.

- The framing components for the grow-beds will be made of 2x4 lumber. All the cuts are straight (again, ignore the portions of the picture where this does not appear to be the case, that was an early draft). Assembly can take place with screws and carriage bolts, the latter for the most significant load-bearing members to add rigidity and strength.

- I will have to double-check the size of the NPT fitting on the bottom of the fish tank, but I believe it's 2". I plan to run the largest diameter reasonable from the fish tank to the grow-beds, to ensure good flow and minimal clogging.

- All the plumbing should be sufficiently accessible. Space is a bit cramped, but I have positioned the system components such that nothing is completely inaccessible.

- All plumbing will be valve-governed. The under-tank plumbing will probably be glued wherever slip fittings are used. This is to mitigate a pressure disaster. Not visible in the picture above is a valved outlet, which could be used to drain the majority of the system if things go very wrong. The valves will allow me to disassemble whatever portions of the system I like - within reason - without having to move the fish and drain the fish tank. Where pressure should not be a significant issue, I will probably use unglued slip joints, as is the common tendency (this allows easy cleaning of the smaller pipes, as they can be disassembled).

- I have tried to design the plumbing such that if there is a pump failure, the entire tank doesn't drain to the sump. The system is configured such that the water in the fish tank must rise sufficiently to spill over into the grow bed flood plumbing. The spillover tube is open at the top (the blue vertical tube in the illustration above), so that no siphon can form.

- Finally, with the size of the tank, grow beds and plumbing, it should be very easy to expand this system by adding upwards of 6 more grow beds, without changing out the tank. Additional sump will be required, if/when we get there.

Related Topics and Research

In doing my extended research, I investigated the keeping of koi. These fish have rather particular water clarity needs, and so I felt they would make a good study in just how clean one could keep a pond or tank, and in what methods would serve to best achieve this. Some of the interesting tidbits I collected from the koi pond building guides were:- Large plumbing is essential. Under-sizing leads to clogging, mainly due to the typically low flow rates.

- In koi ponds, once practice is to feed into swirl filters first, then get to media filters - if you're interested in removing the maximum amount of contaminants and not growing plants with them, that is. Multiple swirl filters can be attached in series.

- Bottom drains work best, as they encourage the capture of just about everything that falls to the bottom (thus my choice in a cone-bottom tank). These are usually built into the koi ponds during construction.

- Pipe purging can be done by creating a fast water flow. In some koi ponds, this is done by disabling the filter feed pipe, draining the swirl filter, then enabling the filter feed pipe. This (theoretically) allows water to flood in rapidly, dragging accumulated contaminates through the pipe and into the filter. I should be able to do the same with my valve system.

- Ideally, the pump should be places after the filtration assembly. This improves pump life and reduces clogging at the pump.

- Any inline heaters, UV lights, anaerobic filtration equipment, water polishing, and such, tend to go after the filters, and either before or after the pump.

While some of these points will not be highly applicable to aquaponics, I think some practices may prove beneficial. In a future iteration I would like to employ some swirl filters to clean the water in prep for delivery to a NFT or DWC array.

Lighting

One of the unfortunate side-effects of using the porch is the lack of direct sunlight. There is plenty of diffuse lighting, but I do not believe that will be sufficient for even my trial plants. I have been investigating various lighting options. Here's what I've considered:

- HIDs - low entry cost but high energy usage and possibly short lifespan of bulbs.

- Metal Halide - bluish light that is good for vigorous plant growth.

- High Pressure Sodium - reddish light that is good for fruiting.

- It is ideal to use both kinds for the different stages of plant growth, but this requires a ballast that can energize both kinds of bulbs (or more than one ballast).

- T5 fluorescents - moderate investment, lower energy usage than HIDs.

- Bulbs reportedly need to be replaced after 6 months.

- LED - higher initial cost, lowest energy usage.

- Research is comparatively scanty on LEDs for plants, but there is a growing industry and community.

- DIY LED lights are possible.

My ideal lighting solution will probably be LED, and by that I plan to manufacture my own grow-lights. There are several how-tos and at least one excellently engineered build-guide. WHen compared to the buy-and-install of HIDs and fluorescents, LED lighting construction is not trivial.

- Power Supply

- An LED driver is required. You can get LED drivers and drive them with D/C power, or purchase an all-in-one driver unit.

- LED Assembly

- Some people use red/blue diodes, others use white.

- Power LED lights require heat dissipation measures - a heat-sink or metal backing plate.

- Cooling

- Passive cooling is obvious and easy.

- Active cooling requires power; the LED power source might provide for this, otherwise separate power requirements must be met.

Aeration

To assist with aeration, I plan on eventually having two systems in place:

- Venturi aerator - this will be driven off the return water feed, so pump-powered and run directly back into the fish tank.

- Air-stone pump - ideally with a backup power supply, this could run air in both the fish tank and the sump.

There are several online examples of DIY venturi aerators. The construction is extremely simple, so I will be experimenting with that as well.

Project Road Map

I will be performing the testing and evaluation step first. All other steps will occur as time and materials become available, so the order of events will not necessarily be as listed.

- Build, test, and evaluate critical system components:

- Siphon construction

- Venturi aerator construction

- LED lighting

- Install the electrical

- Build the grow-bed support frame

- Acquire:

- Fish tank

- Grow beds

- Sump

- Miscellaneous system components

- Plumb the system

- Build the full lighting fixtures

- Grow Bed assemblies

- Build, install, and test the siphons

- Evaluate fill/drain times against estimates

- Cycle the system

- Acquire fish

- Add plants

- Grow!

Subscribe to:

Posts (Atom)