The basic configuration I used was 1.25" for the below-bed siphon and drain pipe, but 2" for the standpipe. This was partly on a whim. I also experimented with a 1.25" standpipe. The 2" worked significantly better, especially draining into the 1.25" lower siphon pipe. It was as though I had simply moved the "funnel" that is commonly used in other configurations down to below the grow-bed. I suspect the funnel action here really has nothing to do with the Venturi effect. More on that below.

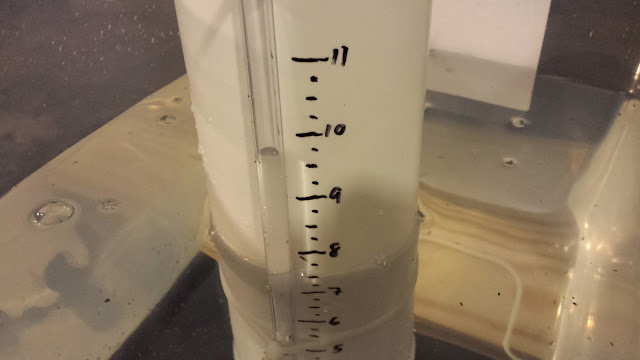

During the tests, I ran the water pump and cycled water between my test tank (a 20 gallon rubber-like plastic container I picked up for cheap) and a makeshift sump tank (a sufficiently large galvanized tub - from whence I bought it, I have no idea). This provided a great opportunity to both test the pump at the likely head-height, in the production plumbing, and to save some water.

The 1.25" standpipe produced a very undesirable result: as water spilled into it, it formed a vortex which was maintained indefinitely. The vortex evidently allowed sufficient water to leave the tank, and prevented siphon formation. The 2" standpipe did not appear to suffer from this problem, and worked repeatedly without fail.

Apropos: my current bell is a 6" diameter PVC pipe, covered with plastic kitchen wrap and "sealed" with tape. The wrap provides a sort of window into the inner-workings of the siphon. My next available bell size is 3", which is too small to work with the 2" pipe and adapters. I am hoping that 4" pipe will offer sufficing inside diameter. The store does not seem to carry 5".

While watching the 2" pipe, I noticed that the flood of water down to the reducer fitting caused enough turbulence and sufficient restriction of flow for a decent blockade of water to accumulate, and thus the siphon would shortly follow. I decided to try relaying in the 3/4" pipe I had installed in the same tub. I used a 1.5" wye fitting, normally used for waste-water collection, and (due to a lack of 3/4" fittings) drove the 1.25" plumbing into the wye at 45 degrees. The 3/4" pipe went straight down into the fitting, and the exit was directly below. Appropriate adapters were used to deal with the size differences. The exit piping was unfortunately a little too short: it ran straight into the sump as I tried to lengthen it.

Unfortunately, it didn't work. The key problem was that there was simply too much turbulence at and after the wye for a good seal to form. Even when the 3/4" standpipe was cut so that it was very close in height to the 2" standpipe, there was insufficient suction to start the 3/4" pipe. I suspect this issue could be averted if the 3/4" was upstream from the 2", and the 1.25" pipe had sufficient horizontal length downstream of the 2" standpipe to ensure a good blockade of water. I plan to retest, using the other 2" bulkhead fitting I have, once I have some 4" pipe.

Regarding Venturi

I am beginning to suspect that at the pressures and water velocities we're dealing with, the Venturi Effect is a negligible effect at best when we examine the funnel-style standpipe. I'd like to propose another hypothesis: mass of water. Let's suppose we have a 5" length of 2" diameter standpipe. Water begins to flow over the top circumference and down the inside faces of the pipe. Let's assume the water flowing down is 0.1" in thickness. Let's freeze this scene as the water reaches the bottom of the standpipe (which is also the top of the 1.25" siphon drain). For a 2" pipe and 5" of length, that's about 3 cubic inches of water. Were we considering the same 0.1" thickness of water inside the 1.25" pipe alone, that would equate to about 1.8 cubic inches of water. In other words, the larger standpipe provides a deluge by virtue of its geometry alone.

Dividing the 2" pipe's low volume of water by the 1.25" pipe's cross-sectional area gives us the result that the same volume of water would occupy 2.43" linear inches of the 1.25" pipe. This, I believe, is the reason the siphon starts so easily with this configuration: that much water flooding the pipe is significantly more than a 1.25" standpipe would have supplied, thus a water blockade can form and induce a siphon.

The picture here attempts to illustrate the example from above. The siphon is in red (2" standpipe, 1.25" drain), water is in blue. The drawing is to scale. The water on either side of the standpipe represents 0.1" of thickness. Realize that the water is actually coming down around the entire circumference of the standpipe opening, and so is much more voluminous than what I can easily illustrate. The water shown leaving the drain pipe (which is pointing down) is the equivalent volume as what is entering the standpipe. It, too, is to scale. As you can see, a relatively small volume of incoming water becomes a relatively large volume of draining water, and should saturate the pipe volume sufficiently to start the siphon.

Were we to use two 2" pipes, or two 1.25" pipes (that is, the same size between the standpipe and the drain), we must then hope that the water level continues to rise sufficiently to eventually saturate the siphon. In the meantime, there would be physically little to stop the water from simply draining through without accumulating. Thus, I suspect the Venturi effect is of little value here, and that the geometry of the pipes provides the most potential benefit.